This workshop is equipped with Hartex Engineering’s Suspended ceiling truck service pit. Equipped with 2 pit bays 26m long, the large vacant area under the steel deck allows operators to accommodate oil tanks within the pit system, largely removing the need for a separate oil store. This particular pit has fixed work platforms, although height adjustable travelling platforms are usually the norm.

For diagnostic purposes, the pit is equipped with two suspension shakers units and a separate roller brake tester bay. The lubrication pumps are from Hartex’s Graco range, which is one for the most durable lubrication pumps on the market today.

All our pit systems are designed in detail using 3D CAD facilities that allow our clients to visualise what they are getting. This is usually an exciting phase for the mechanics and leading hands because we can change positions of jacks, or hose reels or tanks etc on a computer screen to instantly gauge the results of that change. Only when all stakeholders have signed off on these CAD plans do we commence cutting steel.

All our suspended ceiling truck and bus service pits are manufactured in Sydney pre-assembled before dispatch to ensure all components fit together to ensure a timely installation on site. This is very important for both you the operator, and also for the principle builder on your construction project.

The truck service pit undergoing final pre-assembly quality checks in our workshop

The suspended ceiling pit system arrives on site

Equipment is unloaded and placed into the pre prepared pit

Unloading Runways

Unloading Runways

Unloading Runways

Placement of runways on top of the pit

Runways joined together for longer pits

Runways joined together for longer pits

Runaway assembled

Completed pit deck side view

Completed pit deck end view

Fixed working platform for mechanics to reach trucks

Enclosed lubrication hose reels

Hyrdraulic pipe work for Hartex Pit Jack System

The power unit for the suspension shaker mounted inside the pit

Bulk oil tanks and lubrication pipe work inside the pit

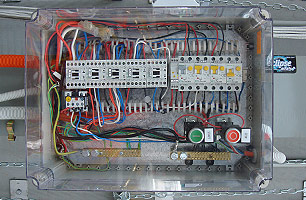

Fan control box to control all power energising in this hazardous environment

Enclosed lubrication hose reels for diff oil, grease and trans oil

Bulk oil tanks wth electronic gauging stored inside the suspended ceiling pit

End view of top deck – the mechanics just loving their new workshop

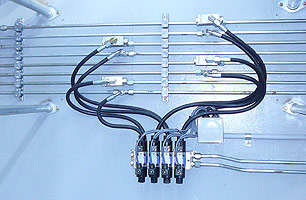

High pressure pipe work for the jacking system

Bulk oil tanks with electronic gauging

Internal end view of the pit (under deck)