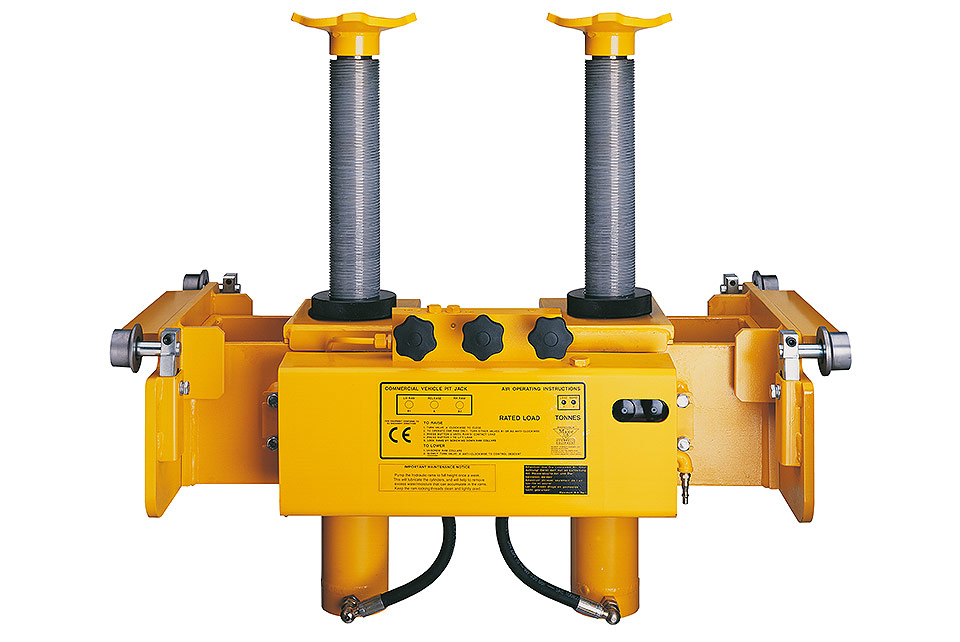

This jacking beam is shipped ready for use. No configuration or assembly required.

It's twin ram operation provides greater operational stability, efficiency and safety. The rans slide transversly, making precise positioning under the vehicle possible. They can also be used independently or in tandem, allowing one or both sides of the vehicle to be lifted.

Surface Engineered for a longer, harder working life - All key components in a Majorlift jack now have their working life greatly extended through a patented surface engineering process. This range of treatments develop iron nitride surface compound layers to toughen the surface and resist rust. The nitrogen-enriched zone can improve yield and fatigue strengths by as much as three or fourfold.

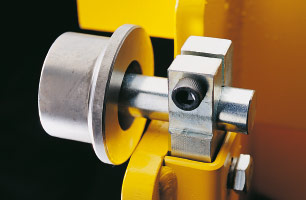

Spring loaded wheel

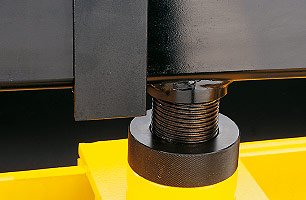

Lock nut to safely lock the jack in elevated position

Push buttons to lower the jack

Jacking bridge with chassis pick up adaptor

Model |

HJB20T |

Twin ram operation |

Greater operational stability, efficiency and safety. The rans slide transversly, making precise positioning under the vehicle possible, AND they can be used independently or in tandem, allowing one or both sides of the vehicle to be lifted |

Pumps can be either air powered or manually operated |

Air gives easy and rapid lift; Manual gives easy double action pumping |

Positive mechanical safety lock on all rams |

Greatly enhanced operator safety especially against accidental lowering |

Newly introduced, load bearing supports and spring loaded rollers |

Smooth, easy and safe movement along the pit |

Accessories supplied as standard |

Benefit beam is supplied complete with a full set of slip-on ram heads to assist in jacking axles, diffs and chassis, etc. |

Control valves as standard |

Precise lowering for optimum safety and working conditions |

Pressure relief valve |

Automatically prevents overloading |

Model |

HJB12T |

Twin ram operation |

Greater operational stability, efficiency and safety. The rans slide transversly, making precise positioning under the vehicle possible, AND they can be used independently or in tandem, allowing one or both sides of the vehicle to be lifted |

Pumps can be either air powered or manually operated |

Air gives easy and rapid lift; Manual gives easy double action pumping |

Positive mechanical safety lock on all rams |

Greatly enhanced operator safety especially against accidental lowering |

Newly introduced, load bearing supports and spring loaded rollers |

Smooth, easy and safe movement along the pit |

Accessories supplied as standard |

Benefit beam is supplied complete with a full set of slip-on ram heads to assist in jacking axles, diffs and chassis, etc. |

Control valves as standard |

Precise lowering for optimum safety and working conditions |

Pressure relief valve |

Automatically prevents overloading |