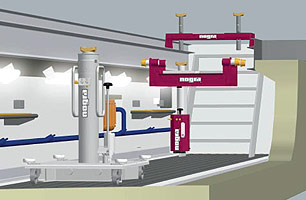

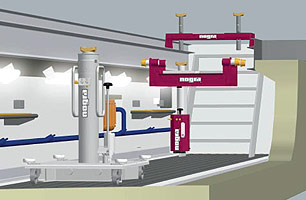

The name ELEPHANT stands for solid and perfected Suspended Pit Lifts. This type of pit jack is a newly developed series.

Not just optically, the new Elephant series is distinguishable from its predecessor. It is the number of new technical innovations that makes the ELEPHANT one of the most modern suspended lifts today.

The pit is first and foremost the central feature of a perfectly functioning workshop

The pit is first and foremost the central feature of a perfectly functioning workshop

PH Elephant Jack, convenience due to pneumatic

PH Elephant Jack, convenience due to pneumatic

quick lifting and pneumatic forced return

PH Floor Jack Eurolift, convenience due to pneumatic

PH Floor Jack Eurolift, convenience due to pneumatic

quick lifting and pneumatic forced return

The pit is first and foremost the central feature of a perfectly functioning workshop

The pit is first and foremost the central feature of a perfectly functioning workshop

PH Elephant Jack, convenience due to pneumatic

PH Elephant Jack, convenience due to pneumatic

quick lifting and pneumatic forced return

PH Floor Jack Eurolift, convenience due to pneumatic

PH Floor Jack Eurolift, convenience due to pneumatic

quick lifting and pneumatic forced return

Model |

PH Model |

Slimline design |

The consistent duo-construction saves space and makes more free space along the lenth of the pit |

Covered Control |

effective protection against impact, which prevents possible injuries to the user. The equipment is also protected against external influences |

Lifting and pump piston hard chrome plated |

Both the piston rod and the pump piston are hard chrome plated for protection against corrosion and wear |

DTS (Dual Tank System) |

Complete oiling of the cylinder - a special process prevents the development of rust at the inner wall of the cylinder |

Hydropneumatic Quick Lift |

The hydropneumatic quick lift rapidly moves the piston rod to the lifting point |

Pneumatic forced return |

The hydropneumatic forced return rapidly retracts the piston even when not under load. Unlike conventional pit jacks, the piston is effectively 'pulled' back into its rest position |

Detachable double pump |

The simple, compact design simplifies regular maintenance work |

Roller with roller bearings |

The bearings in the chassis and cross-trolley allow extremely light movement |

Load depressing safety cross-trolley |

The movement facility under load is disable from a load of approx 800kg. A particularly flat design is also achieved. |

Model |

HH Model |

Slimline design |

The consistent duo-construction saves space and makes more free space along the lenth of the pit |

Covered Control |

effective protection against impact, which prevents possible injuries to the user. The equipment is also protected against external influences |

Lifting and pump piston hard chrome plated |

Both the piston rod and the pump piston are hard chrome plated for protection against corrosion and wear |

DTS (Dual Tank System) |

Complete oiling of the cylinder - a special process prevents the development of rust at the inner wall of the cylinder |

Hydropneumatic Quick Lift |

The hydropneumatic quick lift rapidly moves the piston rod to the lifting point |

Pneumatic forced return |

The hydropneumatic forced return rapidly retracts the piston even when not under load. Unlike conventional pit jacks, the piston is effectively 'pulled' back into its rest position |

Detachable double pump |

The simple, compact design simplifies regular maintenance work |

Roller with roller bearings |

The bearings in the chassis and cross-trolley allow extremely light movement |

Load depressing safety cross-trolley |

The movement facility under load is disable from a load of approx 800kg. A particularly flat design is also achieved. |

Model |

LM Optimum |

Slimline design |

The consistent duo-construction saves space and makes more free space along the lenth of the pit |

Covered Control |

effective protection against impact, which prevents possible injuries to the user. The equipment is also protected against external influences |

Lifting and pump piston hard chrome plated |

Both the piston rod and the pump piston are hard chrome plated for protection against corrosion and wear |

DTS (Dual Tank System) |

Complete oiling of the cylinder - a special process prevents the development of rust at the inner wall of the cylinder |

Hydropneumatic Quick Lift |

The hydropneumatic quick lift rapidly moves the piston rod to the lifting point |

Pneumatic forced return |

The hydropneumatic forced return rapidly retracts the piston even when not under load. Unlike conventional pit jacks, the piston is effectively 'pulled' back into its rest position |

Detachable double pump |

The simple, compact design simplifies regular maintenance work |

Roller with roller bearings |

The bearings in the chassis and cross-trolley allow extremely light movement |

Load depressing safety cross-trolley |

The movement facility under load is disable from a load of approx 800kg. A particularly flat design is also achieved. |