Providing your pit with a good lighting and ventilation system is paramount in order to ensure a safe working environment for your mechanics. The hazardous environment standards AS/NZS 60079 classifies service pits as class 1 zone 2 environments PROVIDED they are mechanically ventilated such that a minimum of 6 air changes distributed evenly across the length of the pit is achieved.

With the Hartex Service Pit lighting system you get a world class product, purpose built for the rugged environment of a busy vehicle workshop.

The hazardous environemnt standards AS/NZS 67009 define all truck and bus service pits as class 1 zone 2 as a minimum, which means special explosion proof light fittings are required to comply under the code.

The heavy duty light fitings supplied y Hartex have a diecast aluminium chassis with toughened polycarbonate lens surable for the environment. All light fittings come with class 1 zone 2 certificates that we provide to the electrician on site in order to prepare the dosier to submit to the electrical authority.

The chassis is made from cast aluminium, the promatic diffuser is moulded in fracture resistant polycarbonate

The chassis is made from cast aluminium, the promatic diffuser is moulded in fracture resistant polycarbonate

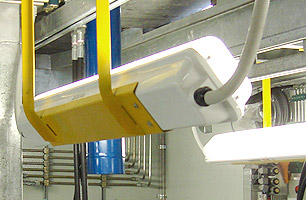

Special brackets to direct light to the underside of the vehicle for Optimum illumination

Special brackets to direct light to the underside of the vehicle for Optimum illumination

Additional lighting installed over oil storage tanks for additional visibility

Additional lighting installed over oil storage tanks for additional visibility

Suspended ceiling pit with lights installed along pit

Suspended ceiling pit with lights installed along pit

Close up of lighting unit.

Close up of lighting unit.

Prefabricated drop-in pit with lighting pre-installed

Prefabricated drop-in pit with lighting pre-installed

Prefabricated workshop pit with lighting added prior to installation

Prefabricated workshop pit with lighting added prior to installation

Special brackets to direct light to the underside of the vehicle for Optimum illumination

Special brackets to direct light to the underside of the vehicle for Optimum illumination

In order to maintain a safe working area and to comply with AS/NZ 60079 the pit must be ventilated to achieve a minimum of 6 air changes per hour. This means all electrical devices in the pit have to be interlocked to the pit fume extraction system.

With Hartex Service pits you get a complete pre wired control box complying with AS3000 to supply power to pit lights, sump pumps, heavy vehicle jacking systems, suspension testers, and any other electrical accessories you may require in your customised pit.

Too often we see drawings and designs for pit ventilation systems with just 3 or 4 air extraction points in a 15m long pit. This is woefully inadequate and does not comply with the standard because this only provides for localised air extraction and there will still remain pockets in the pit with dangerous levels of flammable, explosive or harmful gasses.

You can trust Hartex engineering as the only Australian manufacturer of pre fabricated truck and bus service pits to design a ventilation system that suits your specific pit length or type.

Exterior ventilation ducted unit attached to side of facility

Ventilation unit removing air from within service pit